It is not unusual for construction companies to make investments in information technology. Most of that investment, however, has been focused on enterprise resource planning (ERP) systems in the back office – apeing the strategy of large companies in other sectors.

The construction industry is not like other sectors though. The nature of the product is not uniform or predictable; construction projects are diverse, each carrying with them unique issues and challenges. In addition, around 90 per cent of a construction company’s costs are in the provision of materials, sub-contractors, plant and labour needed to deliver these projects, where margins are thin, risks are high, and change is constant.

Yet the operational and commercial teams tasked with managing these projects are typically relying on a collection of siloed systems and spreadsheets in an effort to create a “single view” of the truth.

In the UK, attempts to make use of ERP systems to control project processes have on the whole been unsuccessful. This has inevitably led to duplicated effort, inefficiency, inaccuracy and a paucity of meaningful information at the sharp end, with genuine implications for overall efficiency and profitability.

Furthermore, this is happening in an environment where the industry is under significant pressure to reduce construction and life-cycle asset management costs, while delivering better value for clients.

For example, the last government’s construction strategy targeted a 15 to 20 per cent reduction in the cost of construction procurement within the public sector, to be delivered through streamlining processes. Looking further ahead, the 2013 government report, Construction 2025, Industrial Strategy: government and industry in partnership, included in its proposals:

- A 33 per cent reduction in the initial cost of construction and the whole life costs of built assets.

- A 50 per cent reduction in the overall time, from inception to completion, for new build and refurbished assets.

The drive to get better value extends to the UK’s infrastructure too. The Highways England Delivery Plan is committed to making capital efficiency savings of £1.21 billion by 2020 (in nominal terms) while delivering an improved service.

In parallel, the government’s Soft Landings programme is designed to eliminate, or at least minimise, the performance gap between design intentions and operational outcomes.

In an industry where low single digit margins are the norm, to paraphrase Einstein: “Doing the same thing over and over again, and expecting different results” just isn’t going to cut it.

For many, building information modelling (BIM) is seen as the panacea, but BIM is still grounded in the design phase of the construction process, and has had minimal impact on managing construction delivery and asset maintenance. Indeed, many of the construction companies that have truly embraced BIM are still struggling with the age-old problem of understanding the true financial performance of their projects.

This brings us back to the need to digitise front-office processes. Unfortunately, the only way that the industry will be able to deliver game-changing efficiencies and savings, and take full advantage of the potential of BIM is if it can firstly integrate the dynamic and ever-changing relationship between time, budgets, cost and value.

Reporting in 2014 on the poor performance of a leading UK construction contractor, KPMG gave one reason as: “Accuracy of cost and programme forecasting – insufficient visibility, control and understanding on actual versus reported contract performance.”

KPMG recommended that project managers should have greater financial and commercial accountability for project performance with an appropriate set of project key performance indicators.

As data enters the Causeway system, it enables us to capture and compare across asset types some real-time and historic benchmarking data. This is key as our clients seek to understand how their assets can be most efficient over a life cycle and is ultimately where we add value most

So this raises a key question: will diverting IT dollars from monolithic back-office finance systems towards agile front-office operational systems offer greater scope for the process transformation and success the industry craves?

The answer must be a resounding yes. If project and commercial managers at the coalface are to be given greater responsibility (and risk), they also need the tools to do their job efficiently. They need systems that bring together all the business processes associated with cost-capture and management of project. They also need to be able to share that information with supply chain partners and, ultimately, clients’ systems in integrated project teams.

This approach played a key role in the successful delivery of London Heathrow Airport’s Terminal 5, where BAA managed a single team of more than 50 contractors and mandated the systems they used, with Causeway solutions at the heart of them.

That was in 2008 so this isn’t a new concept, but the sustained focus on back-office ERP has undoubtedly hindered its adoption.

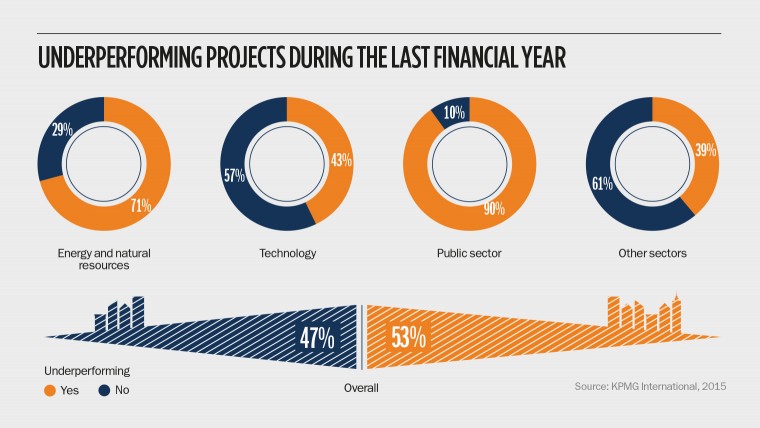

In fact, as integrated project teams become the norm, there is a strong incentive for clients to take more responsibility for the systems being used. As KPMG notes in its 2015 Global Construction Project Owner’s Survey: “Project owners must invest in relationships with contractors to raise mutual trust and discuss problems or shortcomings. Rather than simply passing all or most of the risk to the contractor, it is preferable to create an integrated project team with common goals and rewards.”

As with capital projects, contractors operating in asset maintenance need tools that will help them minimise costs and increase client satisfaction through better management of their precious resources. Causeway has observed that customers who integrate job processes with mobile technologies, GPS telematics and scheduling can increase the efficiency of mobile workforces by as much as 30 per cent.

So the good news is that things are starting to change, albeit rather slowly, and the technologies and know-how are now there to support digitisation of construction’s “front office”. The challenge is to make it happen quickly enough and that may well require a change of thinking at board level.

Discover four ways to digitise your front office now at go.causeway.com/future or contact phil.brown@causeway.com

CASE STUDY

RICHER DATA FOR REPORTING AND BUSINESS INTELLIGENCE

EM Highways provides highways maintenance services to a number of strategic clients. The company introduced Causeway as its core front-office business system in 2013 and has seen turnover increase by £210 million to £500 million.

Finance director Joe Incutti recalls: “We looked at systems, such as Oracle and SAP, and realised quite early in the process that the Causeway solution, off the shelf, was going to be a very good fit. We decided we were going to implement the lot, not just take bits and try to integrate it with other bits of systems – we were going to use the whole thing from cradle to grave.

“Having that fully integrated suite of products gives us a much richer extraction of data from the system for reporting and business intelligence.”

Since implementing Causeway, EM Highways has:

- Doubled in size, scaling the Causeway solution in line with this dramatic growth.

- Automated numerous previously laborious, time-consuming front-office processes.

- Streamlined production of all key management reports.

- Come top in Highways Agency StART scores, with much credit given to the supply chain collaboration support provided by Causeway.

- Used the partnership with Causeway as an exemplar for BS 11000 accreditation.