Manufacturing is a moneymaker for the UK. Contributing some 11 per cent of total economic value, the sector makes more than £1 in every £10 going into the nation’s pocket.

What’s more, the public know this to be true: some 70 per cent agree the UK cannot tackle future problems without a strong manufacturing sector, according to a survey carried out for Make UK, The Manufacturers’ Organisation.

For all its success, however, manufacturing in the UK needs to develop and change, if it is to continue as a driving economic force for

future generations.

The good news is that the sector is not short of ideas. Visiting hundreds of manufacturing businesses over the last 12 months, Make UK chief executive Stephen Phipson has been struck by the level of clever innovation happening all around the country. “Whether big or small, every enterprise has an innovation story to tell. How they have survived and thrived is often down to thinking differently about both product and process,” he says.

“As a result, this differentiator comes through very strongly for the UK in our brand reputation within export markets. Innovation is our unique selling point; innovation in everything we do.”

Manufactured goods account for about 44 per cent of total UK exports and this revenue stream is a magnet for inward investment. It is why so many household global names are here.

The latest figures put the UK ninth in the world for manufacturing by value of output; however, this story is not well understood by the general public. In fact, the same survey respondents, who consider the sector important to the nation’s economic future, actually guessed the country came as low as 56th in the rankings, a position currently held by Kazakhstan.

Indeed, problems with public perceptions of the manufacturing sector are proving a significant obstacle to progress in the UK. For instance, only 17 per cent of people surveyed realise average earnings in manufacturing exceed those in the wider economy.

This failure to communicate carries potentially serious consequences in terms of human resource. Manufacturing already employs around 2.7 million people in the UK and rising demand for engineering skills could mean as many as 265,000 new recruits a year through to 2024. Getting and keeping sufficient skilled bodies on board, therefore, calls for significant uplift in attraction and retention of talent, plus retraining.

The challenge begins with the education system, right from primary school level upwards, argues Mr Phipson. “We need to attract young people into this profession. However, over the last couple of decades, design and technology in schools has almost disappeared, with the system skewed towards getting more and more people into university. The upshot is a gap in intermediate technician-level skills,” he says.

“This skills gap has largely been filled by the free movement of labour from Europe, with a lot of the 300,000 EU nationals currently employed in manufacturing working as toolmakers, machine-setters, CNC [computer numerical control] programmers and the like.”

With Brexit on the horizon, however, availability of this supplementary skills resource hangs in the balance. Therefore, manufacturers are increasingly looking for learners with a combination of vocational and academic profiles, which is what makes degree apprenticeships so attractive.

Complicating recruitment matters more, though, gender balance has also been a workforce issue in manufacturing, historically. National statistics show women only make up 24 per cent of employees, barely one in four. They represent just 11 per cent of engineers and 15 per cent of engineering graduates.

While the sector itself is responding, greater urgency is needed, as well as a more systemic approach to working with educators and policymakers to address structural issues.

The recent Reinventing the Manufacturing Workforce report from Make UK revealed the majority of manufacturers, some 72 per cent, are introducing or continuing formal apprenticeships to help secure the skills for the future. Slightly more are offering agile ways of working to retain existing employees, plus over half offer flexible forms of employment.

Altogether, developing a modern, youthful, diverse and appropriately skilled workforce fit for 2019, Brexit and beyond calls for something of an image makeover on the part of UK manufacturing. Spearheading this charge will be Make UK, pioneering a proactive stance to update perceptions and broaden appeal.

Core to a new vision for the sector is the positive impact of the fourth industrial revolution (4IR). Digitisation is transforming much of manufacturing already and its influence will only continue to disrupt the world market, in a good way, explains Mr Phipson. “Overwhelmingly, 4IR provides a fantastic opportunity for the sector in the UK. In truth, we have lagged behind somewhat on digitisation, but that future catch-up factor only serves to make the size of the prize even bigger,” he says.

“Digitisation is not just the domain of major players, though. Investment of £1,000 in smart sensors on a CNC machine could harvest data and double SME [small and medium-sized enterprise] productivity within a month.

“Change at scale and pace will, however, require substantial reskilling of an existing workforce new to such areas as data analytics. Therefore, we are very pleased that government policy under the Industrial Strategy is supporting this with the Made Smarter initiative and £147 million of allocated budget to help technology diffusion become a reality up and down the supply chain.”

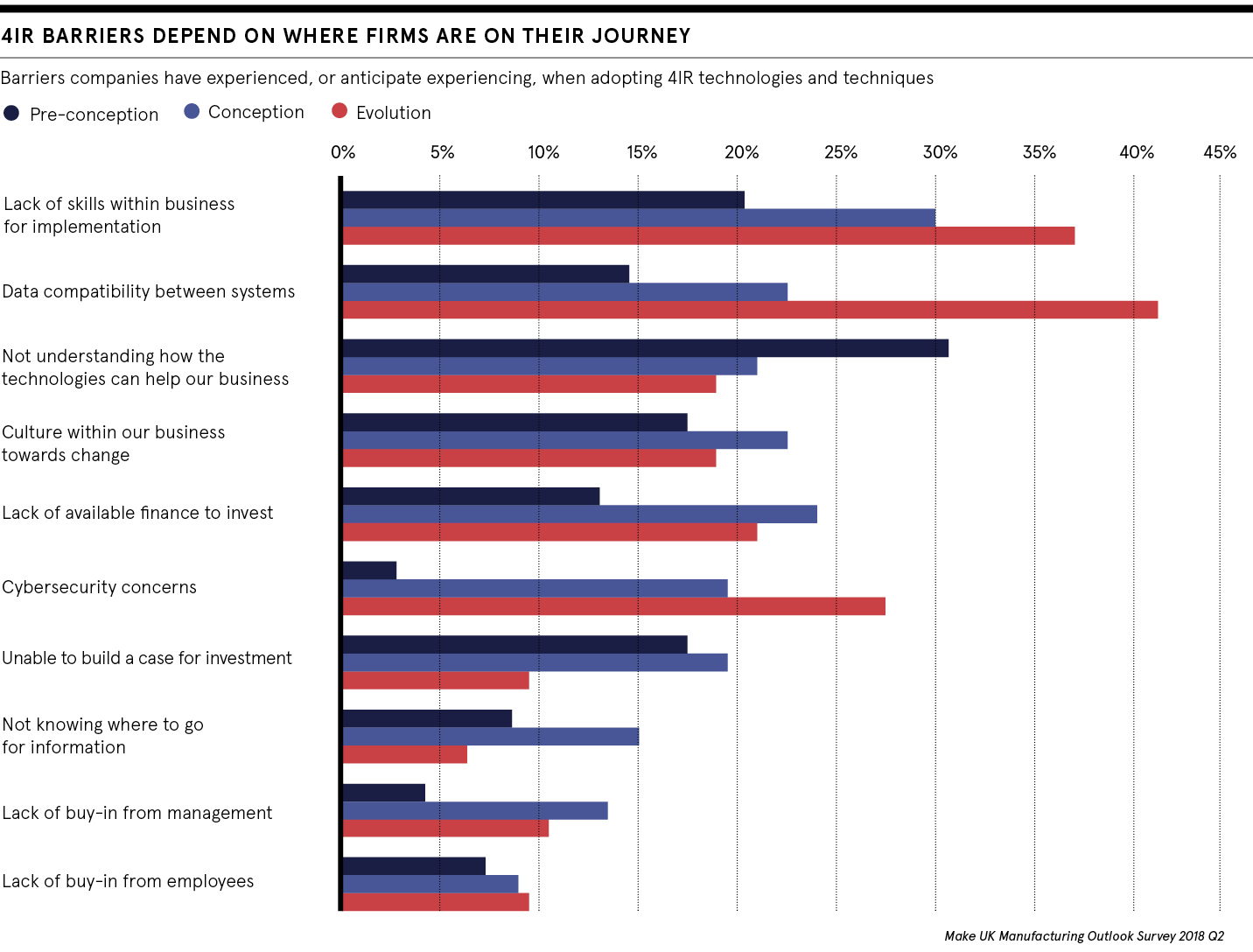

Make UK research suggests 43 per cent of manufacturers have moved beyond the initial conception phase on 4IR into the evolution phase, where current business practice is optimised with new technologies. In short, they have moved from thinking to doing. That still leaves a majority yet to invest. For UK manufacturing to remain a future moneymaker, however, 4IR is a must. The future is inescapably digital.

Mr Phipson concludes: “The effects of digitisation are going to touch everything. Instant mass customisation of products means manufacturing in real time, on demand, using state-of-the-art technology, such as 3D printing. It will revolutionise the way we make things.

“While the risk is real, the opportunity is huge. With our genius for innovation, backed by a consistent policy framework, plus an image makeover, 4IR is a new dawn for manufacturing in the UK.”

For more information please visit makeuk.org