The ways in which product designers select materials for projects has for many years remained unchanged. The prevailing tendency is one of human nature, towards a reliance on experience, existing contacts, web search or sticking to the same range of materials they know has worked well before.

The ways in which product designers select materials for projects has for many years remained unchanged. The prevailing tendency is one of human nature, towards a reliance on experience, existing contacts, web search or sticking to the same range of materials they know has worked well before.

This tendency has been further cemented by a need to meet numerous strict standards in materials, particularly around safety. Many designers respond to this by staying with previously used materials and may be unaware of equivalent materials standards that permit a range of alternative selections.

Designers’ reliance on existing ways of working has limited innovation. It has also left open enormous scope for them to offer much more interesting and effective solutions to their manufacturing clients.

Using new tools, designers and manufacturers can shake off less effective ways of working and instantly tap an online database of materials to transform their product creation

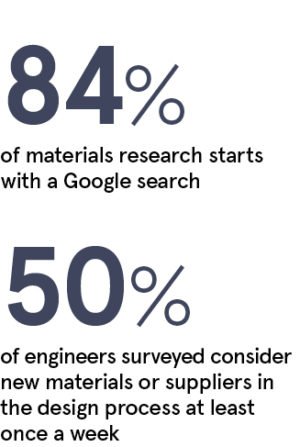

Some 84 per cent of product designers and engineers still carry out a simple Google search as their first port of call when looking for materials for a project, according to research by online materials platform Matmatch, in conjunction with BCG Digital Ventures. Other key resources include supplier websites and scientific journals. People typically search for the elements, materials, brands and standards they already know, rather than seeking new items.

“We’ve found that designers and material engineers, when they take on a new project, tend to start with their own knowledge and explore limited places from there,” explains Melissa Albeck, chief executive of Matmatch. “They think along the lines of materials that have worked well for similar applications in the past. And those materials might well do the job, but there could also be something out there that would really be a much better fit for that product.

“In effect, many designers’ reliance on web search engines as the primary means through which they look for materials has a problem consumers know well; they start by typing in terms they already know something about. The aim for us is to help people break out of that cycle and give them instant access to information on other viable and potentially more advantageous alternatives.”

Matmatch is opening up an easy route to finding and accessing these other materials, having developed a free-to-use online platform, which allows designers to search a database of more than 80,000 different materials, including metals, polymers, ceramics, glass, composites and biological materials. Designers can assess the particular properties of different materials, compare their viability for specific uses and discover equivalent standards of the available materials where needed.

“Until now, a lot of people have tended to rely on their own knowledge, or asked people around them, because it has been so hard to find the right data. That’s the issue we are solving,” says Ms Albeck.

Matmatch’s database gives product designers access to a range of key details about different materials, with all the information having come from reliable sources and verified by an in-house team of material scientists. The company also uses machine-learning to predict materials data and sees potential in using technology to match designers with materials automatically.

Crucially, suppliers of many materials can be contacted directly through the platform, enabling orders to be placed easily. Before Matmatch, companies would have had to search, sometimes extensively, for where to procure those materials.

The platform, designed to provide users with a much more straightforward route to pertinent information, is used among product designers and engineers creating prototypes for everything ranging from wind turbines to ship parts to consumer goods and beyond.

A development engineer at a major sports carmaker recently found the platform useful as a means of identifying quality materials and suppliers for vehicle interiors. Typically, in the car industry, designers would search online, visit exhibitions and discuss the details with contacts before deciding on materials for a new project.

A key benefit of Matmatch’s system proved to be the ability to have an overview of, and comparisons between, different material suppliers. The engineer comments: “Exhibitions contain mainly a closed circle of companies and to open that circle with a platform will be important in making materials sourcing in the automotive industry more dynamic.”

For smaller firms too, the potential impact of opening up free access to vast swathes of data, on tens of thousands of different materials, is essentially limitless. Innovation around materials has tended to be the preserve of some of the very largest companies. Apple, for example, might roll out a new product using a completely unconventional material. But as Ms Albeck explains: “It has the resources and in-house expertise to focus on experimenting with multiple unusual materials where others generally would not. Now other companies can more easily try useful alternatives.

“Historically, smaller companies have perhaps lacked the resources to spend lots of time or money on research and therefore consider alternatives. That restricts innovation because, if they’re not looking into the options and asking if there might be better materials available, then it is harder to take things to the next level.”

With the Matmatch platform being free to use, it is expected to democratise information across industries, encouraging consistent innovation from early-stage startups to large businesses.

Ultimately, for Matmatch, the goal is to continue opening up and making more easily digestible details on as many different types of material as possible. There is already information on more than 80,000 distinct materials on the company’s database, but more are being added every day.

By using the new tools, designers and manufacturers can shake off less effective ways of working, and instantly tap an online database of materials to transform their product creation.

To find out more about how to find the best innovative materials for powerful product design please visit matmatch.com